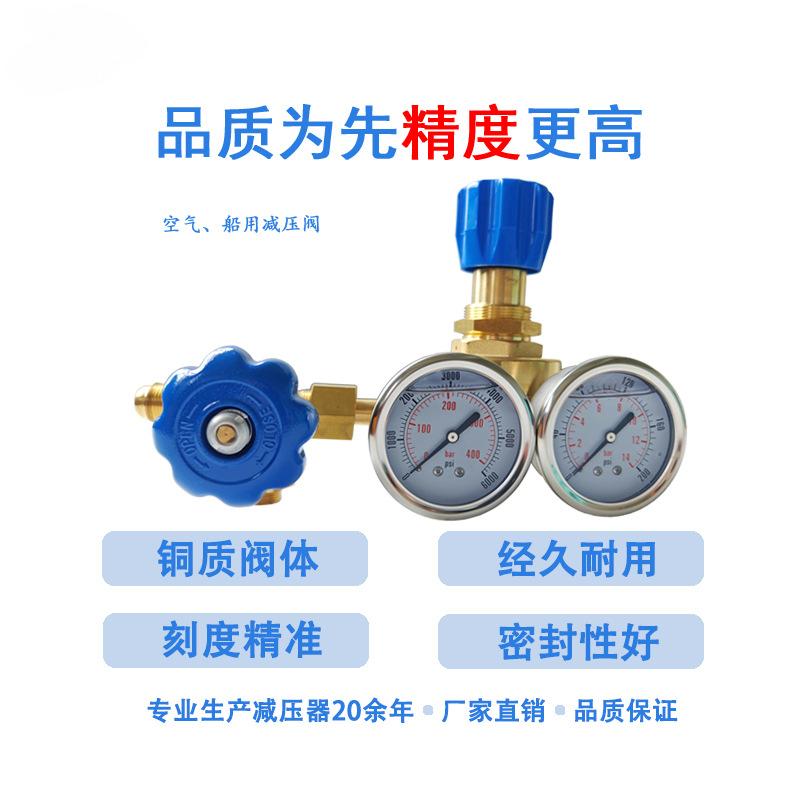

YQK-299 Marine pressure reducer

Model: YQK-299

Measurement range: 0 - 1.4 MPa.

Purpose: Marine pressure reducer.

Structure: Single-stage type.

Marine pressure reducing valve.

Inlet connection thread: Connect to pipeline.

Outlet connection thread: High-pressure pipe.

Name: Marine and air pressure reducing valve.

Material: Copper valve body.

Model: QJ20-8T.

Net weight: 3KG.

Explosion-proof air high-pressure pressure reducer, submarine lifeboat pressure reducer, marine pressure reducing valve.

Model: YQK-299

Measurement range: 0 - 1.4 MPa.

Purpose: Marine pressure reducer.

Structure: Single-stage type.

Marine pressure reducing valve.

Inlet connection thread: Connect to pipeline.

Outlet connection thread: High-pressure pipe.

Name: Marine and air pressure reducing valve.

Material: Copper valve body.

Model: QJ20-8T.

Net weight: 3KG.

Characteristics: It is an indispensable and important component on ships. Its function is to control the internal pressure of the ship's system and ensure the normal operation of ship equipment. The marine pressure reducing valve protects pipeline equipment from damage by adjusting the pressure and flow of the medium, and at the same time ensures the stable operation of the fluid system. This kind of valve plays a key role in the ship's system. Whether it is controlling fluid pressure, flow rate or flow direction, it is extremely important.

Introduce the application fields of marine pressure reducing valves.

1. **Consider pressure parameters**

- **Inlet pressure range**: It is necessary to clarify the pressure range at the inlet end of the pressure reducing valve in the ship's system. For example, in the high-pressure fuel delivery system of ships, the inlet pressure may be as high as several megapascals (MPa), while in some domestic water systems, the inlet pressure may be relatively low. Select a pressure reducing valve whose inlet pressure range can cover the actual system pressure to avoid damage to the pressure reducing valve due to excessive inlet pressure or inability to work normally due to too low inlet pressure.

- **Outlet pressure requirements**: Determine the outlet pressure according to the specific needs of ship equipment. For example, in the hydraulic system of a ship's steering gear, the normal working outlet pressure is generally within a specific range (such as several megapascals) to ensure the precise operation of the steering gear. A pressure reducing valve that can accurately adjust and stably output the required outlet pressure should be selected to ensure that ship equipment operates under appropriate pressure.

- **Pressure regulation accuracy**: For some systems with high pressure accuracy requirements, such as the precision instrument cooling system of ships or some high-precision hydraulic control systems, a pressure reducing valve with high pressure regulation accuracy should be selected. For example, a pressure reducing valve with an accuracy of ±0.01 MPa can better meet the needs of such systems and effectively avoid damage to equipment due to excessive pressure fluctuations.

2. **Flow demand matching**

- **Rated flow**: Understand the flow rate of the fluid (such as hydraulic oil, water, gas, etc.) passing through the pressure reducing valve in the ship's system. In the hydraulic system of a ship's cargo crane, the flow rate is relatively large. A pressure reducing valve with a rated flow that can meet the maximum flow demand when the cargo crane is working should be selected to ensure that the cargo crane can lift goods quickly and smoothly. Generally, the product specification will indicate the rated flow range of the pressure reducing valve, and selection should be made according to the actual flow situation of the system.

- **Flow characteristic curve**: Different pressure reducing valves have different flow characteristic curves, which reflect the change of flow under different pressures. For some ship systems that need to maintain a relatively stable flow under different pressures, such as the ship's fire water system, a pressure reducing valve with a relatively flat flow characteristic curve should be selected. In this way, during the fire water spraying process, even if the pressure changes to a certain extent, the flow of water can be relatively stable, improving the fire extinguishing effect.

3. **Medium compatibility**

- **Medium type**: The ship system involves multiple media, such as fuel, lubricating oil, water, various gases, etc. Ensure that the material of the selected pressure reducing valve is compatible with the medium. For example, for a ship's water supply system that transports seawater, a corrosion-resistant pressure reducing valve should be selected. The valve body material can be copper alloy or stainless steel, etc., to prevent the pressure reducing valve from failing due to seawater corrosion.

- **Special medium requirements**: Some ships may use special media, such as some special fuels containing additives or chemical gases for fire extinguishing. In this case, special attention should be paid to whether the sealing materials and other components of the pressure reducing valve are compatible with these special media. For example, for a fire extinguishing system that uses halon fire extinguishing gas, the sealing material of the pressure reducing valve needs to be able to withstand the chemical properties of halon to avoid leakage.

4. **Explosion-proof and safety requirements**

- **Explosion-proof level**: In some areas of ships where there are flammable and explosive media, such as near fuel tanks or compartments with combustible gas equipment, pressure reducing valves that meet the corresponding explosion-proof levels must be selected. For example, in the cargo oil loading and unloading system of oil tankers, a pressure reducing valve with an explosion-proof level of ExdⅡB T4 or above should be selected to prevent explosion accidents caused by sparks generated by the operation of the pressure reducing valve.

- **Safety certification**: Priority should be given to selecting pressure reducing valves that have passed certifications of relevant international or national classification societies (such as China Classification Society CCS, American Bureau of Shipping ABS, etc.). These certifications ensure that the pressure reducing valve complies with ship safety standards in terms of design, manufacturing and performance, and can operate safely and reliably under various ship operating conditions.

5. **Environmental adaptability**

- **Temperature range**: The temperature change range of the ship's operating environment is large, from cold polar seas to hot tropical seas. For pressure reducing valves installed on open decks or compartments without insulation measures, consider the temperature range it can adapt to. For example, ships sailing in the Arctic region may face extremely low temperatures for their external equipment. The selected pressure reducing valve should be able to work normally in a low-temperature environment to prevent component damage or performance degradation due to low temperatures.

- **Humidity and salt fog environment**: In the marine environment, the humidity is high and there is salt fog. For pressure reducing valves that are exposed to this environment for a long time, they need to have good moisture-proof and salt fog corrosion resistance. For example, pressure reducing valves with protective coatings or special sealing structures can better resist salt fog corrosion and extend service life.

6. **Installation and maintenance convenience**

- **Installation size and connection method**: Ensure that the installation size and connection method of the pressure reducing valve match the existing pipeline system of the ship. For example, the inlet and outlet connection threads of the pressure reducing valve (such as G1/2, G3/4, etc.) should be consistent with the interfaces of the ship's pipelines for convenient installation. At the same time, its external dimensions should be suitable for the installation space to avoid inability to install or affect surrounding equipment due to excessive size or small size.

- **Maintenance requirements**: Select a pressure reducing valve that is easy to maintain. For example, some pressure reducing valves have simple internal structures and parts that are easy to disassemble and replace, which is very beneficial for the repair and maintenance of ships during navigation. In addition, whether the product has a clear maintenance manual and technical support is also a factor to be considered, so that crew members can perform correct maintenance operations when needed.